概述:

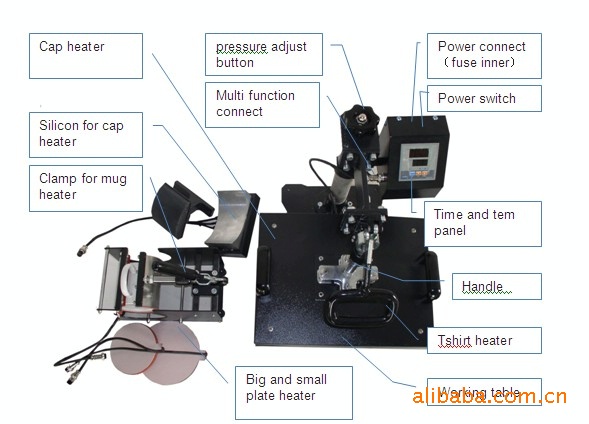

多功能配置=烤盘机(两种尺寸)+烤杯机+烤帽机+烫画机

本机为多功能一体机,可以烤杯、烤盘、烫画、烤板,烫帽、并且可以扩充其它加热部件,可升降180度旋转,便于取物及一定厚度的物品之转印;主机设计方便更换不同功能之转印部件快速便捷,不需工具。

特点:

自动稳定的电子数据温度指示器,具有很高的精确度。

有独立电路控制箱方便更换仪表。

加热线和加热板集成在一起,安全耐用。

自动的时间控制表

耐高温硅胶垫,使压力更加均匀,180旋转。

压力调节方便,照片都可以被印在衣服.领带.杯子.帽子.瓷砖.盘子等

可以扩充加热部件,占地小,功能多。

使用说明

提起手把,使机器成张开状。在工作平台上放上要烫印的物体,测试压力是否合适,如不合适,需调节压力旋钮。(顺时针旋转旋钮为加大压力,逆时针旋转为减小压力)

张开机器,准备好待烫印物。(升温过程请不要将待烫印物放置在工作平台上,以免烤坏)

打开电源开关,温控仪开始自检,约10秒后自检完成并进入工作状态,此时才可设置工作参数,(第一次使用请设置好所需:温度、时间,详见后附仪表面板时间与温度操作说明)

设定好需要的温度、时间,机器开始升温加热(温度上升至200℃大约需要15分钟)

待机器达到所需温度时,将需要转印的物品平铺放置在工作台面上,压下手把,机器开始自动计时,达到设定的时间后,机器发出警示音,提起手把完成一次操作。

保修:

感谢您选择我们公司的产品,您享有我司对本产品实行的一年免费保修服务。对于我司没有维修网点的地方或者国外,我们只能提供替换配件并通过远程协助来指导顾客自行维修;对于超过保修期的我们仍然提供技术支持与维修指导

属下例情况,我们可能酌情收取配件成本费:顾客未安要求或因操作、维护、运输不当而造成产品损坏或出现故障的。

Double boxed -Each machine is double-boxed before it leaves our warehouse. These machines are decently packed from the factory in corrugated cardboard boxes and protective Styrofoam. However, shipping carriers are sometimes very-rough in handling heavy packages. It has been our experience that the standard packaging many times will result in damages to the units, and insurance claims are difficult and time-consuming. To remedy this and protect your purchase, we double box every unit. We do this in addition to the full Styrofoam encasement and heavy-duty inner box. We are the only seller that we‘re aware of taking this extra step, but in our opinion, it‘s a must.

Versatile operation -Five separate heating elements allow transfers onto a variety of items, such as fabric, metal, ceramic, wood & glass. Create your own custom t-shirts, mouse pads, plates, coffee mugs, ball caps, tote-bags, license plates, and many other unique & fun items.

Easy to use -Arrives fully assembled and ready to use (printer and paper not included).

Swing-away design -This design is an improvement over clamshell designs, as pressure is directed straight down and is therefore more evenly applied; this improves the quality of the finished transfers. Full 360-degree rotation of swing arm; allows the heating element to be moved safely aside, reducing the chances of accidental contact.

Digital LCD timer -Preset desired time and an audible alarm will sound when time is complete; helps avoid over exposure.

Digital LCD temperature control -Set the desired temperature (in Fahrenheit) and element will stop heating when preset temperature is reached.

Full-range pressure-adjustment knob -Easy to access, top-mounted control. This allows the pressure to be adjusted according to the thickness of the material you‘re transferring to.

Coated handle -Comfortable rubber grip for everyday-use and long production runs.

Adjustable multi-spring balancer -Handle applies closing pressure through a spring and pressure-plate system, which allows pressure to be more evenly distributed across the entire platen when clamshell is closed.

Teflon-coated elements -Unlike other machines with bare-metal heating elements, all elements included with this machine, except for the cap press, are teflon coated. These surfaces are non-stick, prevent scorching of transfers, and don‘t require separate silicone/teflon sheets. The cap press is machined from high-grade aluminum, and due to its size, shape and design, it does not require special sheets either.

Removable lower platen -Lower platform is elevated with dual supports; these allow room for t-shirts to be easily placed into and removed from the machine, and the supports allow the platen to be easily swapped to convert the machine into a cap press.

Upgraded cradle -Detached cradle for use with included mug heating element. The cradle measures 11" x 6" wide and includes coated handle and rubber bumper feet to protect your working surface.

Rigid steel frame -Machine is heavy-duty, commercial-grade, super stable and built to last.

Summarization:

Multifunctional heat press machine is consisted of 5 accessories they are:Tshirt heating plate ,mug heating plate,cap heating plate and plate heating plate (two size).

This machine enjoys multifunction in one machine,it can be used for transfering on tshirt,mug,plate,cap and so on. Moreoverthe heating accessory can bejoined .It can be circumvolved 180degrees and is convenient to take off the transfered materials and can be used for transfering on certain thick materials;you can replace the heating plate easily and conveniently without using any special tools.

Usage

1.Turn up handle bar,let the machine open. Put the materials which you want to do the transfer on the working table,adjust the pressure (turn clockwise to add the pressure,turn anti-clockwise to reduce the pressure)

2.Open the machine,,prepare the materials。(to avoid burning out, Pls don’t put the materials on the working table when it is in the process of heating )

3.Connect the power line which comes with the machine,turn the power on ,the controller will check automaticly ,the machines will work after 10secs,then you can set the time and temp,(for the first time pls set the right time and temp,more details you can see the usage of the display of controller box.)

4.Set the temp and time,machine start heating up (then arrive at 200degree,it needs about 15minutes)

5.When the temp arrives at which what we set,put the materials on the working table, then turn down the handle bar,and the time begins to count,when the time’s up,machine alarm,turn up the handle bar ,then finish it.。

ATTEN:The function of the temp controller is complex,pls don’t press any button for other operation unless you set up the temp ,otherwise the process of the controller will be damaged !!!